|

|

|

||||||||

Mazda FE3 motor

By Randy Stocker

NOTE. This page is mostly just a stream of consciousness and copied text from the flood of emails I get.

|

The 1988-1992 Mazda 626i 16V used a 16V DOHC version of the venerable 2.0 FE SOHC motor called the "FE3" . It was only offered in Europe and Japan and never came to the States. I first learned of the FE3 from Mazda Master Tech Alan Johnson. Back in 1996 he made an innocuous and in-passing comment to me while I was getting my Miata serviced by him "you need to look at the Sportage engine", as if he was telling me the guarded secret to eternal life. I pondered this statement for 4 years until one day I was at a local Mazda salvage yard and spotted what I thought was the elusive grey-market FE3 engine. The rest is history. |

NEW 10/01/01! read Jay's FE3 page

NEW 10/23/01! read "FE3T" FE3 specs page! page NEW 5/6/02! Danny's FE3 Miata 450 rwhp, TII trans, TII rear! NEW 5/17/02! Oddball Racing's turbo FE3 B2200 truck NEW 6/27/02! Aussie FE3T site! NEW 6/27/02! David Coleman's FE3 compilation page |

The "FE3" engine is actually called the "FE DOHC" within Mazda but the part number nomenclature begins with FE3N so most people just refer to it as the FE3. The FE3 is an interesting engine. By the early 80's Mazda had already developed a diesel engine variant from the FE family. The only major change to the FE design for use in the diesel was to change the block casting to add more oil return passages (says a lot about the duty strenth of the F engine family) and to go to an 8 bolt flywheel flange onthe crankshaft. By the time the mid 80's rolled around the public was demanding DOHC heads on engines so Mazda basically raided the parts bin and used a slighly updated version of the 'RF' diesel block and added an aluminum DOHC head of very similar design to the existing B series DOHC head.

Since the FE3 motor was never imported into the States in any Mazda vehicle the only source, other than importing, is the 95+ Kia Sportage. The 95+ Kia version is the same except it is detuned with less compression ratio, ECU tuning and manifolds designed for torque.

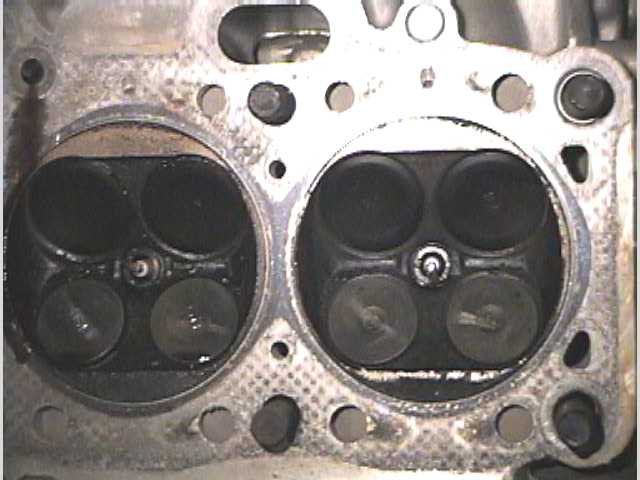

The DOHC head is the real centerpiece of this motor. It's design is almost identical to the DOHC 'B' heads except for everthing being larger. The ports are much larger than 1.8 and the valves are also larger than the 1.8. The stock FE3 head flows 234 cfm intake and 194 cfm exhaust at 28 inches water (for comparison a 1.6 head is about 170'ish intake and a 1.8 head is about 210'ish intake). The factory redline is 7000 rpm with a 7300 fuel cutoff (same as the Miata).

as you can see the combusiton chamber is identical to a 'B' DOHC. The valves are larger than a 1.8 at 34mm intake and 29mm exhaust.

as you can see the combusiton chamber is identical to a 'B' DOHC. The valves are larger than a 1.8 at 34mm intake and 29mm exhaust.

The crank and block are substantially beefier with larger journals, rods (22mm wrist pins), 11mm between cylinders, -- even the head bolts are larger to 14mm from 12mm.

Click to enlarge. As you can see the FE3 FWD intake manifold gasket is nearly identical to the F2 12V gasket. It looks like a port blend using a massive gasket match and a few mounting holes drilled in the flange will do it. Note how much larger the FE3 ports are.

16V DOHC intake manifold flange

16V DOHC intake manifold flange

FE3 exhaust manifold. Actually a nice design. Too bad it is heavy cast iron.

FE3 exhaust manifold. Actually a nice design. Too bad it is heavy cast iron.

Different shots of the 16V DOHC VICS intake manifold

The FE3 block is the same design as the vernerable FE 2.0 and F2 2.2 as found in the 84-92 626 and MX6 and the 88-92 Probe. This block has 11mm between the cylinders which means a much larger overbore can likely ocure. The primary difference that makes the FE3 and FE/F2 blocks non-interchangable is the oil return passages.

FE3 top, FE/F2 bottom

FE3 top, FE/F2 bottom  2.0 RF diesel

2.0 RF diesel

As you can see from the pic the FE/F2 have basically one large center oil return passage (separated by a divider) while the FE3 has three separate oil return passages. If one were to attempt to put a FE3 head on a FE/F2 block you would have to block two of the oil return holes in the head which may lead to oil pooling and possible leaking past the valve seals. Note, the 2.0 diesel, "RF" is based on the FE design but has nearly the same block as the FE3 (and possibly a forged crank - although an 8 bolt flywheel flange!). Also be aware the 2.2 diesel "S2" is an entirely different engine design and it's crank will not fit the FE/F2 family of blocks (BTDT - got the t-shirt).

The FE and F2 SOHC heads use a closed combusion chamber. The pictons are correspondingly dished. The FE3 DOHC used an open combusiotn chamber and the pistons are classically domed.

The DOHC would not be easy to adapt o the SOHC block. Two of the three oil passgages don't align and since the SOHC uses a closed chamber head with dished pistons then using the open chamber DOHC head will lower your CR a lot (something like 3 pts!). Custom pistons are likely to be part of the recipe.

The head gasket is the 1.2mm thick composite unti just like the 1.6 B6P material.

Left is a 8V 2.2 F2 NA. Huge dish. (Four valve reliefs because the piston can be reversed)

Middle is 12V 2.2 F2 NA. Not as deep of a dish but still too much for DOHC head.

Right is obviously the 2.0 16V with a slight dome.

The 2.2 F2 block is 14.5mm taller than the 2.0 FE block. This height difference is made from the 8mm additional stroke (86mm vs 94mm) and 6.5mm longer rods (152mm vs 158.5mm). The crank journal and main diameters are identical. so ... The cam belt from the FE3 will not fit a 2.2 block because of the length difference. You would have to source your own from some other application. 14.5mm is just too much to shave from the block deck :-).

A 2.2 crank will fit in a 2.0 block if you determine how to remove 8mm from the piston height and/or compression height (pin height). There is only 7mm from the top ring groove to the top of the piston, even leaving say 3mm for integrity leaves only 4mm from shaving the top of the piston. You would have to find an additional 4mm which leaves custom pistons with wrist pin height (relocated oil control ring groove height to accomidate) as the only source. (A DOHC Toyata Supra belt can be used to make up the taller enngine height)

Other pistons I will look at are the 3.0 liter V6 from the 929 and MPV that came with the same 86x86 bore and stroke of the FE 2.0, and it was DOHC from 92+ so that may be another source for domed DOHC pistons (the SOHC are heavily dished). Haven't seen the rod length or journal diameter yet so that is next to read. The new 2.4 Quad 4 and Honda H22/H23 pistons look promising too. The Kia FE3 also uses the 8 flywheel flange pattern of the RF diesel. If I kept the engine at 2.0 liters I would either have to use the Sportage flywheel or install a genuine Mazda flywheel with the standard 6 bolt flywheel. There does not seem to be any 2.2 forged cranks. Every 2.2 I opened up for had pictured taken of had a cast crank. I'm not too particularly worried about it as I'm not aware of anyone ever having crankshaft problems with a 2.2 - the mains and rod journals are huge and turbo guys take the 2.2 engine to 20 psi all the time. The 2.0 does seem to have rare forged cranks (identifed in the classic manner of a thick mold line vs a thin casting line). They came on either the 90+ 170 hp FE3's (non-cat, 10:1 CR, aluminum oil pan) or the RF diesel. The diesel has an 8 bolt flywheel and the later high output FE3 is rare. I have only seen three forged 2.0 cranks.

The FE3 engine I located is going to get a stroke and bore job to 2.3 liters and then installed in a Miata using a B2000/B2200 transmission bellhousing case.

Below is the log of the project started in the summer of 2000 ....

UPDATE 10/5/00

Purchased a 1990 140 hp genine Mazda FE3 from a local salvage yard. It was from a AWD so it has the aluminum pan and forged crank. I just finished pouring over the 98 Kia Sportage shop manuals I just acquired. Looks like the remaining parts I need can be had from the Kia FE3 motor (primarily coolant plumbing like the intake pipes/manifolds, thermostate housing and the corresponding cam sprocket cover).

The genuine Mazda FE3 does not have this front thermostat housing so the Sportage items need to be transfered.

The genuine Mazda FE3 does not have this front thermostat housing so the Sportage items need to be transfered.

Interestingly, the Kia version uses coil on plugs and not a separate coil assembly. The cam angle senor drive on the exhasut camshaft is different so I might have to use a crank trigger style wheel or swap to a genuine Mazda FE3 exhgaust cam. With the real Mazda FE3 enigne you could use a good ol' fashion CAS. The Kia exhaust cam also a round dowl pin style drive so it will be incompatable with a Miata CAS. A Genuine Mazda FE3 exhaust cam will need to be sourced to Drive the Miata CAS.

Also, I noted the cams specs in the Sportage manual are the same as the 9.4:1 spec cams for the Mazda FE3. (BTDC 10, ABDC 55, BBDC 55, ATDC 10, 45.052mm total lobe hight). I can only assume then that the 130 hp rating of the Kia is only held back primarily by the exhaust manifold/downpipe and the ECU tuning. The very small 130cc injectors (air shrouded type so no direct aftermarket interchange without installing a adapter like MSD or Electromotive sells or creative use of o-rings) and the smallish throttle body (twin 46mm) don't help either. The Sportage also has pistons with a sligh dish to them and rated at 9.2:1 pistons vs the genuine Mazda FE3 has pistons with a slight dome to them giving 9.4:1.

The stock cam specs are:

20 degrees overlap (10 BTDC, 10 ATDC).

245 seat-to-seat duration (180+10+55)

1.411" basecircle (35.84mm).

1.772 lobe (45.005)

.361 lift (9.17mm)

UPDATE 2/22/02

After a year of planning and false starts, finding a new job and rebuilding the engine on my racecar I have started serious work on the 2.3 stroker FE3 for the Miata. The oil pressure on the 1.6 is getting lower by the day so I don't know how long it will hold out. I sold the genuine Mazda FE3 to JayB back in '01 after I decided to use a Sportage engine afterall. I researched that it is identical to the genuine Mazda FE3 for my purposes (i.e. stroking it) and it already has the proper RWD coolant plumbing. The Sportage motor has the same head, same ports, same valve diameters, same block, etc, as the genuine Mazda FE3.

Almost all of my work will be in the short block and in packaging it for the Miata engine bay. The Sportage head has the same sized valves and the same double valve springs as the genuine mazda FE3. With a turbo I don't really care too much about the cam profile as boost will make up for any low lift and duration specs and the overlap (20) will be OK for boosted anyway. I'm shooting for 240 rwhp from a 7 psi non-intercooled 2.3 liter using the stock 1.6 ECU, RX-7 flowmeter, ACU and 326cc injectors.

Here is a pic of the port of the Sportage intake manifold. You can see the huge mispatch between the head and the intake manifold. I have a lot of grinding ahead of me.

Here is another pic of the height of the lower half of the Sportage manifold. I'll have to be creative with the 1.6 Miata plenum I'm welding on to it to keep the heigth low enough to close the hood.

With the 2.2 stroke job in the shorter 2.0 block I knew I would need a custom set of rods and pistons to make it all fit within the block height. I surfed and surfed the web and created a rods cross reference spreadsheet to see if I could find a rod from another engine instead of having to get custom rods created for $1000.

I decied on and found some nice over-the-counter Crower Chevy forged rods for the stroker FE3 on the cheap. The FE/F2/FE3 engines use a crank rod journal that is 2.005" and a rod with a 2.126" big end and a big end width of 1.055". Rods from the 153/194/230/250 Chevy L4/L6 are standard early Chevy sized at 5.7" long (144.78mm) with a 2.125" big end (for a 2" crank rod journal) and are 1.029" wide on the big end. To use the Chevy rods all I would have to do is grind the crank .005" undersize. Crower makes a forged rod for these engines that is made from 4340 chromoly steel, weighs 585g, and rated for 8200 rpm and 500 hp. Part number SP3208 and they only cost $297 for a set of 4! - much better than $1000 for a custom set!

But this also leaves a rod side clearance of .026" when the Mazda shop manual calls for no more than .012". I called a couple of engine builders and they all said that .026" is a little big for a street motor but they said they all build circle track motors with .028" side clearance so as long as I use standard tolerance rod bearings so the rod can't move around too much on rotation I should be OK.

With the 5.7" rod (144.78mm) and the 94mm stroke of the F2 the crank the rod ratio will suck at 1.54:1. I'm not to concerned about it as the 1.8 BP is just slightly better at 1.56:1 and I will chamfer the botton of the cylinder bore and dry film coat the skirts to help with skirt scuffing. Again, this is just a street motor that will see light boost. (note a 6" Chevy Rod is avialable as part number SP93209).

The FE3 block can have up to a 3.5" bore (88.9mm or +2.9mm) so I surfed the internet looking for 3.5" pistons that use the standard Chevy wrist pin diameter of .927". At first I located the 3.5" pistons that are in the 200 V6, 267 V8 or the Vega but they are all low performance cast units. The only dimentions that were a little off is that most of the Chevy pistons have anywhere from a 1.500 - 1.540" compression height depending on aftermarket manufacturer and I need something like 1.470" to fit the stroker F2 crank with a 5.7" rod. The 3.5" V6 and V8 pistons have a .120" dish with a 1.540 compression height. Stock replacement Vega pistons are flat top with anywhere from 1.473 -1.500 compression height. I ordered a set of Clevite cast Vega Pistons as they measured 1.473" and the flattop should give somewhere around 9.3:1 CR. (Forged Vega pistons used to be available in Sealed Power part number L2401F but they have long since been discontinued).

Crower SP3208 rods description

Keith Black/Silv-o-lite psitons

UPDATE 3/22/02

Purchased a 626/Probe flywheel for use on the F2 crank. The flywheel and crank that comes with the sportage uses 8 bolts to hold the flywheel on while the Mazda FE and F2 cranks use 6 bolts. The 626 flywheel is also substantially lighter. The 626 flywheel uses the same clutch as a 2nd gen RX-7 so there are lots of performance options out there. Even more details later...

UPDATE 5/10/02 Progress slow this month. I found the Sportage block I was using had a crack in the cooling passage on the exhaust side so I have been busy trying to source another block. When the stock replacement Clevite Vega pistons arrived I was taken back by the low quality. I was concerned they would not take 6-7 psi of boost and 7300 rpm so I returned them. At the same time I did however score a nice set of brand new forged JE custom 89mm forged full-floater Cosworth Vega pistons made for a 6" rod (1.430" compression height) so the compression height was about right where I needed it at just 1mm below deck. The pistons are great and already have the four valve reliefs for a DOHC head. They only weigh 380 grams! I *love* Ebay! Also purchased a nice set of Sealed Power premium piston rings (part# E345K) for $25 (JC Whitney even sells an inexpensive set of Grant rings for $16 - I love the cost of Chevy parts!)

This combined with the Crower Chevy forged rods should make for a reliable foundation good for 500 hp!

The local fabricator did a nice job with the intake manifold. A 1.6 upper plenum welded to a Sportage lower. Since the Sportage uses those unique air shrouded style injectors and I'm going to use standard style injectors I might be able to pump cold water through the passages to super cool the manifold??

Pics of the injector setup next time...

Make sure to check out Danny's page (pages 3 & 4) to see the motor mounts and oil pan he fabricated for his drag car!

UPDATE 11/15/02

While waiting for the machine shop to finish their work on the 2.3 shortblock I replaced the oil pump and shimmed the pressure relief spring in the 1.6 this summer. No help to speak of.

Here is the pic of the completed shortblock. Currently the only 2339cc FE3 in the USA (note the 6 bolt F2 crank). The rod side clearance with the Chevy rods prooved not to be an issue. The longer 2.2 crank throws in the 2.0 block and the clearance with the oil squirters also were fine. The only surgery required was to take .120" off the counter weight length to keep from hitting the bottom of the cylinder bore and shaving the block deck .050" to make the pistons zero deck (the 5.7" Chevy rods and 1.430 CH Cosworth vega pistons were about 1mm short). If I had to do it all over again I might use oversize Honda H23 2.3 pistons (1.203" CH) at 88mm and the factory 152mm SOHC FET rods. This would allow a better rod ratio of 1.62 and allow the use of the factory head gasket which supports +2mm overbore. Another option is the Nissan VG30DETT/SR20 pistons (1.260" CH) with the factory 150mm rods. See rods cross reference sheet I created. The factory FET rods are actually quite stout.

Next is to section the oil pan to try and lower the engine in the subframe as much as possible and then assemble the remainder of the engine by putting the head and intake manifold on with the ported HKS BP turbo manifold. I've decided to use injector bosses in the intake manifold since the bores for hte odd air injection fuel injectors that the Sportage uses probably won't keep the o-ring seated as well as I would like.

UPDATE 12/07/02

Had the oil pump blueprinted to make sure it flowed as much volume as possible with the increased tolerence of the rod side clearance. The factory blueprint is .004" between the gears and the cover plate. I had it machined to .001"

The factory NA 626 flywheel is quite heavy at 29 lbs. I had the back side and back side ring machined and 5 lbs came off. Now weighs 24 lbs. Not bad!

UPDATE 6/26/03

The last outsourced fabrication is DONE! Custom fabricated oil pan to fit the Miata chassis started as a Sportage pan. The sump was shortened and moved rearward to match the Miata pan and fit in the subframe. The whole pan was shortened to be able to lower the engine in the bay about 1".

UPDATE 7/22/03

The last month has been productive...

1) Clutch install. Used a lightened MX-6 flywheel with 225mm clutch and new B2000 pilot bearing.

2) The FE3 engines is about 1 inch longer than a 1.8 which moves the front pulley very close to the front swaybar. I first attempted to modify the Sportage 3 groove pulley but it was just too long to use. I then modified a 2 groove MX-6 pulley and the length was just right leaving about 1/8" before the swaybar.

The MX-6 uses the same 6 bolts to attach to the lower timing belt gear but has a different patten. Only two of the holes line up so had to oblong the 4 other holes. Locited in place.

The MX-6 uses the same 6 bolts to attach to the lower timing belt gear but has a different patten. Only two of the holes line up so had to oblong the 4 other holes. Locited in place.

3) Made motor mount adapter plates from 1/4" steel. The engine will be slid into the engine bay and a reference mark made for the factory 1.6 mounts, then new bolt holes drilled in the plate.

4) The Sportage has the alternator and AC mounted on opposite sides than the Miata. Fortunately the MX-6/Probe has them mounted on the same side as the Miata. Use '84-92 alternator mounts and 89.5-92 AC brackets. I opted to modify the Miata AC compressor mount to keep it low in the chassis same as the Miata position (the MX-6 puts it up a little high for my taste)

5) The 3mm overbore allows for lots of room to unshrowd the valves. I was able to remove around 4mm of material!

6) pic of the injector bosses I had to install in the Sportage lower manifold in order to use standard style injectors instead of those "air shrouded" units.

The porting to blend the intake manifold flange to the head, smooth the welds internal to the runners, unshrowd the valves, gasket match to the overbored throttle body and blend the bosses was extensive - over 50 hours of grinding!

UPDATE 8/10/03

BP turbo exhaust manifold is modified and on the engine. Getting a little closer closer ...

BP turbo exhaust manifold is modified and on the engine. Getting a little closer closer ...

UPDATE 9/7/03

AC is done. What a PITA!!! The stock FE/F2/FE3 has the AC in the upper right position (up high). I wanted it in the stock Miata position so the hoses and wires would not have to rerouted/extended but to also keep the weight and center of gravity low. Since there are no factory brackets that put the AC in the Miata positon for the FE/F2/FE3 block I had to massage the Miata pieces to fit.

First was the compressor bracket. The bosses on the block are completely different and on the Miata block they are not all on the same plane - some are deeper set than others. I used 3 of 4 bolt holes. The first hole was repositioned to the lower left to postion the compressor pulley in line with the crank pulley. The new hole is still on the cast bmouting boss os it fits flat. The back two holes were reused and bolted to a 1/2" thick bracket that mounted to 3 bosses on the block. The perpendiculat mounting hole that anchors the bracket fore and aft was reused but by removing the center spacer to allow the the larger FE3 bolt to fit offset in the hole and also shaving the water pump slightly to make everything fit. The block needed various trimming and cutting to make it all attach correctly. By far the largest hassle to date.

The belt adjuster required a lot of head scratching to get right. I used a combination of Miata non-PS idler pulley parts and the factory FE/F2/FE3 AC adjustor with a custom built 5" longer pulley extension from 1/4" steel. Careful use of spacers and washers made exerything align.

UPDATE 9/14/03

After looking intently at the alternator bracket for an hour one night I decided to not bolt it directly to the block and instead opted for a rod end to attach it to the block. Bolting the alternator adjustment bracket directly to the block causes a bind and gives only had about an inch of adjustment so a spacer to move the bracket out away from the block and to the left is needed. Mazda uses the front motor mount bracket as a spacer in FWD applications and Kia used the the fan idler pulley as a spacer. Since I wanted to use neither of these big hunks of cast iron I just bent the end of the steel adjustment bracket with the attachment hole 90 degrees and double nutted a rod end into it. The rod end then bolts to the block and serves as the spacer.

After even more head scratching I decided to do a "coolant reroute" - actually the native FWD route - instead of using the Miata/Sportage path. Not for the cooling benefits (see Miataforum.com for details if you just said "huh") but rather because none of the Miata manifolds fit the Kia head properly and it would have been simply too much work to adapt them. I used a 323 thermostat cover and water inlet manifold I had laying around. I located a 1.5" diameter aluminum pipe of about .090" wall thickness for the rear to front transfer pipe. The only hurdle is that the Kia head has no taps for the two rear coolant sensors or heater core and I don't have a tap for the large ECU sensor (1/4" BPT ?). I did tap the head for the smaller gauage temp sensor and tapped the front cover for the fan temp sensor.

UPDATE 9/21/03

Now for the all important CAS... The Miata 1.6 ECU uses a crank angle sensor (CAS) instead of a distributor like the FE3. The Miata CAS does physically fit into the head of a FE3 but it will not function because the slotted drive is much longer on the FE3 distributor so the shorter Miata drive does not make contact with the exhaust cam. (Note, only the genuine Mazda FE3 exhaust cam has the slotted drive for the CAS, the Sportage uses a dowel pin).

I thought briefly about making a drive entension from an old camshaft but that seemed like a lot of unnessessary work and potentially damaging it it ever let go. Fortunately, even though the FE3 uses a distibutor it is optically driven same as some CAS units of the Miata (some Miata's are optic and some are magentic, You have to open them up to tell) so swapping guts is possible. Opening the FE3 dizzy up reveals that the disk that controls the light cannot just be swapped. It has the same 4 light slots that control the spark firing (the Ne signal, one per cylinder) but it doesn't have the BDC slot that the Miata uses for the waste spark (the G signal, one long for TDC and one short for BDC). More important is it's drive key is at a different location rotated approximately 45 degrees to the left.

The way I solved this first I got very lucky and found a genine Mazda FE3 distributor and exhaust cam for sale withthe proper slotted drive. Next I decided to modify the FE3 CAS disk by adding the BDC slot as opposed to tring to reindex the Miata disk to fit the FE3 drive. I used the Miata disk as a pattern to drill and file a new BDC slot being very careful not to bend or damage the disk. I taped the two disks together as the Miata disk acted as a template and gave it the needed strength for drilling so not to bend or crimp. Next was deciding what to do for a cover. A cover is required as any dirt, dust or debris would surely kill the CAS. You can't just use the FE3 distributor cap as a cover as it would foul the firewall. Another lucky fortune was that the Miata CAS cover is very close to fitting the FE3 housing. A little trimming with tin snips, oblonging the mounting holes and sealing with RTV (the FE3 housing has no provisions for the Miata o-ring) and you have an instant FE3 CAS.

UPDATE 1/4/04

Used the 4 day weekend to try and make some progress.

swap 2000/B2200 front trans case to Miata trans

swap 2000/B2200 front trans case to Miata trans

Used B2000/B2200 throwout bearing and fork as Miata TO bearing is too small for the NA 626 225mm clutch

Used B2000/B2200 throwout bearing and fork as Miata TO bearing is too small for the NA 626 225mm clutch

... in with the new. Far bigger dimentionally than the B series engine.

... in with the new. Far bigger dimentionally than the B series engine.

I'm pretty sure a hood scoop is in the future as the intake manifold height is just too high

I'm pretty sure a hood scoop is in the future as the intake manifold height is just too high

The sectioned Sportage oil pan is only about 3/4" below the subframe, I can live with that. Maybe I'll add some plate for protection?

The sectioned Sportage oil pan is only about 3/4" below the subframe, I can live with that. Maybe I'll add some plate for protection?

This installation exersize wasn't just to test my vocabulary of swear words but to measure and make the motor mounts and to test the fitment of all the plumbing. Note the trimming of the CAS mount I'll need to do because of the heater core and the relocating of the front swaybar mount because of the AC compressor. The best part is I get to do this all over again! I wonder if it will take me 6 more months to get to it?

UPDATE 4/10/04

There was supposed to be an autocross next weekend I was going to attend but it was canceled so I used the time I was going to prepare the racecar to work on the FE3.

The FE3 head has 4 bosses cast into the rear of the head for sensors. The genuine Madza FE3 has all of them tapped and used and the Kia has none tapped. I first tapped the two on the side (see cooling reroute above), similar to the original Miata locations, when I realized that location would interfere with my coolant return pipe routing. I then drilled and tapped the top locations.

Genuine FE3 has all 4 bosses tapped.

Genuine FE3 has all 4 bosses tapped.

Kia has none tapped. I drilled and tapped

Kia has none tapped. I drilled and tapped

Used the original Kia rear blockoff cover to block the front.

Powered By Kia. Tag frame worth 50 hp, at least!

Powered By Kia. Tag frame worth 50 hp, at least!

================================== Q & A ==================================

(Q) Why all the hassle for 240 rwhp? Boosting an existing 1.8 to 12 psi is not hard and gets the same power level.

Because it's there. :-) For me the challenge of the custom fabrication and packaging is the fun and not just the instant gratification of power.

For those not so inclined but rather seek power ... if boosting a 1.6 gets your interest imagine boosting a 2.3? My line of thought is that I wanted 240 rwhp, I could have boosted my existing 1.6 with 15 psi or boosted a swapped 1.8 to 12 psi but IMO, that makes the 1.6 is little too high stress for my taste and also requires lots of money for programmable fuel injetion, tuning and intercooling. Boosting a 1.8 to 240 rwhp with 12 psi is not really "stressed" but still requires the fuel injetion, tuning and intercooling. Getting 240 rwhp from a 2.3 only requires 6 psi which makes it a very low stress engine and requried no elaborate programmable fuel injection, tuning or even intercooling if you dont want to. Plus with 2.3 liters you get the advantage of a 94mm stroke for much more torque than you can get with a 83.6mm stroke. When my 1.6 engine started going south I saw the 2.3 as a way to get 240 rwhp and have it be low maintenance and reliable engine that would last another 100K. If you apply that same 15 psi system to 2.3 liters you are looking at nearly 400 rwhp.

(Q) Why?

I chose this conversion for myself because I like to put big engines in little cars and enjoy fabricating things that don't exist in the wild.

1) The FE3 can be cheaply stroked with the 2.2 crank

2) A trans can be easily made to bolt-in and retain the PPF

3) Keep it all Mazda.

4) The required fab work (trans, manifolds, plumbing, CAS, mounts, oil pan) are not outside my abilities or desire to do.

5) If someday I desire more power the FE3 will easily support it.

6) TORQUE

7) Boosted Miata engines are like bellybuttons ... everyone has one.

(Q) I was told the B-series engines are stronger than the F-series Mazda engines. True?

Not really. While it is true the latest variant of the BP is factory rated at 142 crank hp and the latest FE3 is rated at 140 crank hp (Sportage) the torque and performance potential goes to the FE3 hands down.

The latest '99-03 BP is rated at 140-142 crank hp/120 ft lbs primarily from the higher CR pistons, redesigned head and stronger cams over the Mk1 BP. The current FE3 is factory tuned similar to the Mk1 BP era which was 125-133 crank hp /112 ft lbs. A FE3 tuned similar to the current BP level (10:1 and better cams) had 170 crank hp in other markets.

If the FE3 would have had contined factory development and tuning I'm sure the base engine would have 155-160 hp by now and a performance version at 180-190. One only needs to look at the new MRZE engine to determine that (really a continuation/evolution of the FE engine family, ala LS-1 vs LT-1).

The F series engine is Mazda's big block and the B series is the small block.

The DOHC BP does come with a forged crank (SOHC is cast) and most FE3's is cast. That is true only because the BP desparately needs it. With the power level it is tuned to and the smallish 45mm journals a cast crank would not last long. note: the rod bearings are always the first to go out on a BP and typically show signes of wear around the 40-60K mark, a FE3 has no such issues with the phyisically larger hard-parts.

In the world of reliable street engines (not one-run wonders or dyno queens but 50K mile daily drivers), the BP can be boosted to about 250-275 rwhp before aftermarket rods are needed. That same formula for a FE3 would be around 400 rwhp for a stock long block.

If you are not doing anything to a junkyard engine and just bolting it in then a current generation BP would be as strong as a FE3. If you plan to pump up the power beyond, say 250 to 300, then a FE3 is the better bet.

(Q) How tall is the FE3 engine?

I just took a tape measure out to the garage. (not accurate to the .001" but a close enough for government work). My FE3 has a 11.5" block, the head is 5.5", the total engine height at the front w/sectioned oil pan (where the steering rack would be) is 21.5" to the top of valve cover and 22.5-23" to top of intake manifold/turbo.

Compared to a stock FE3 my engine has a .050" shaved block, a thinner .040" head gasket, a .020" shaved head and a 1" sectioned oil pan... or approx 1 3/32" shorter overall height.

Campare this to approx 19.5" total Miata engine height (bottom of oil pan at front to top of valve cover).

I'm still trying to get it to fit the stock hood without a scoop although it will be tight. I will be knocking out some of the hood bracing around the intake manifold and turbo. I may also have to resort to subframe spacers if needed. Simply trial-and-error fitment and packaging.

The major difference between my packaging and Danny's will be the intake manifold and turbo manifold. He made custom pieces to fit below the valve cover height and I used modified stock items so mine stick about an inch over the valve cover.

(Q) What would the horsepower of a NA 2.3 be?

Depends on what level of tuning you have. If you keep it to the same level as stock then you can expect around 160. Here is a thread at miataforum that discusses that very question.

(Q) Does the FE3 block use the same engine mounts as on the F2 engine?

Yes

(Q) Can the F2/F2T's transaxle mount onto the FE3?

Yes

(Q) Where did you get the engine you imported? (from what place)

You can get them from any engine import place. Search the internet or your local yellow pages for "Import Japanese used engines".

(Q) Do you happen to know the engine model code for the FE3's turbocharged brother?

I'm not aware of a turbocharged FE3 sold by Mazda to the public. The turbo 2.2 SOHC 12V is "F2T"

(Q) The FWD intake of the 12V F2 will mount onto the FE3 head with some modification, right?

I would say with a lot of modification. The Sportage intake manifold will not fit the hood line of the MX-6/Probe so you'll have to transfer the 12V intake manifold (primarily just a huge gasket match and redrill a couple flange holes with one hold-down bar for the center stud)

(Q) The bolt pattern for the F2/F2T manifolds and FE3 are completely different.

Exhaust yes - not even close. Intake is similar but different.

(Q) What are the major differences between the Sportage FE3 and the genuine Mazda FE3.

Practically none from a longblock perspective. Both blocks are identical externally with the same mounting bosses for brackets. The only major thing is the 8 bolt diesel flywheel flange vs the 6 bolt of the Mazda. Both engines have the same oil squiters, same forged rods and same head. The Sportage ex cam uses a dowel pin to drive the CAS vs a slotted drive for the Mazda.

Minor things include: the Sportage does use a deep rear sump oil pan that fits few chassis's but that is easily swapped for a FWD or truck version (preferably the aluminum version from the 170 hp or AWD cars). The Kia version eliminated the rotating ex valve keeper locks - most people upgrade to the classic style of the Kia anyway. The Kia pistons are 9.2:1 vs 9.4:1 of most of the Mazda FE3's (the 170 hp '88 non-cat version had 10:1). The Kia cam specs are identical to the 9.4:1 mazda FE3 version (only the 10:1 had a stronger cams). The oil pumps are identical as far as I have seen. The 170 hp Mazda verison has a stiffer relief spring but you can do the same with just a washer. The Sportage and Mazda FE3 both have a cast crank (Only a few cast aluminum oil pan AWD FE3's came with a forged crank). While the blocks are the same the coolant routing is different between FRD and RWD. For a FWD using a Sportage engine just transfer the outlet manifold from your current engine to the back of the head of the Sportage engine and then plug the front thermostat housing with freeze plug (that is what the factory did)

(Q)What do I need to swap a Sportage engine into a Probe?

Make sure to read the FAQ's at www.probetalk.com and MX6.com as they spell it out pretty well and there are people there who have done it.

Swap all brackets and sensors from your FE/F2 - plug the front coolant passage in the head witha freeze plug. Modify 12V F2 intake manifold to fit. Modify a BP EX manifold to fit. Use the Kia flywheel. The hard part is the ignition. The Sportage uses a different CAS. I haven't looked into the signal differences but likely you'll have to use an aftermarket ECU to accept the signal or source a genuine Mazda FE3 distributor to use with a Protege/Escort GT ECU.

(Q) I don't know about you, but I've been unable to get any FE3 parts, only whole motors.

What are you looking for? As posted at www.probetalk.com and mx6.com in their FAQ's:

2) The VW VR6 valve springs are reported to be a performance drop in.

(Q)What transmission do I use for a FE3 swap into a Miata?

A 84-93 B2000/B2200 (with the FE/F2 engine) is the only Mazda RWD trans that bolts up to the FE3 engine. Actually, for a Miata you only use the front housing of the trans and then bolt it to the Miata trans to retain the PPF mount (or the opposite of using the Miata tailshaft extension on the truck trans but then you'd have sucky ratios). The truck trans and the Miata trans are of the same family and one is no stronger than the other. The 2WD Sportage from 98-2002 used a getrag trans(95-97 was the same Mazda unit). Not supposed to be any stronger although the case has more ribs for less case flex - and has no provisions for a factory PPF mount.

(Q)What motor mounts do I use for a FE3 swap into a Miata? Is it a bolt-in?

Motor mounts are custom. I made mine from modifying 1.6 Miata mounts.

The FE3 engine is much taller (3.5") so be prepared to get a custom oil pan created to lower the engine in the subframe. You will also need a custom intake manifold made as the FWD points the wrong way and the Sportage goes over the top. It is not a pure bolt-in conversion but close and should be well worth the effort.

Let me know what you think about my page. Send mail by clicking here.